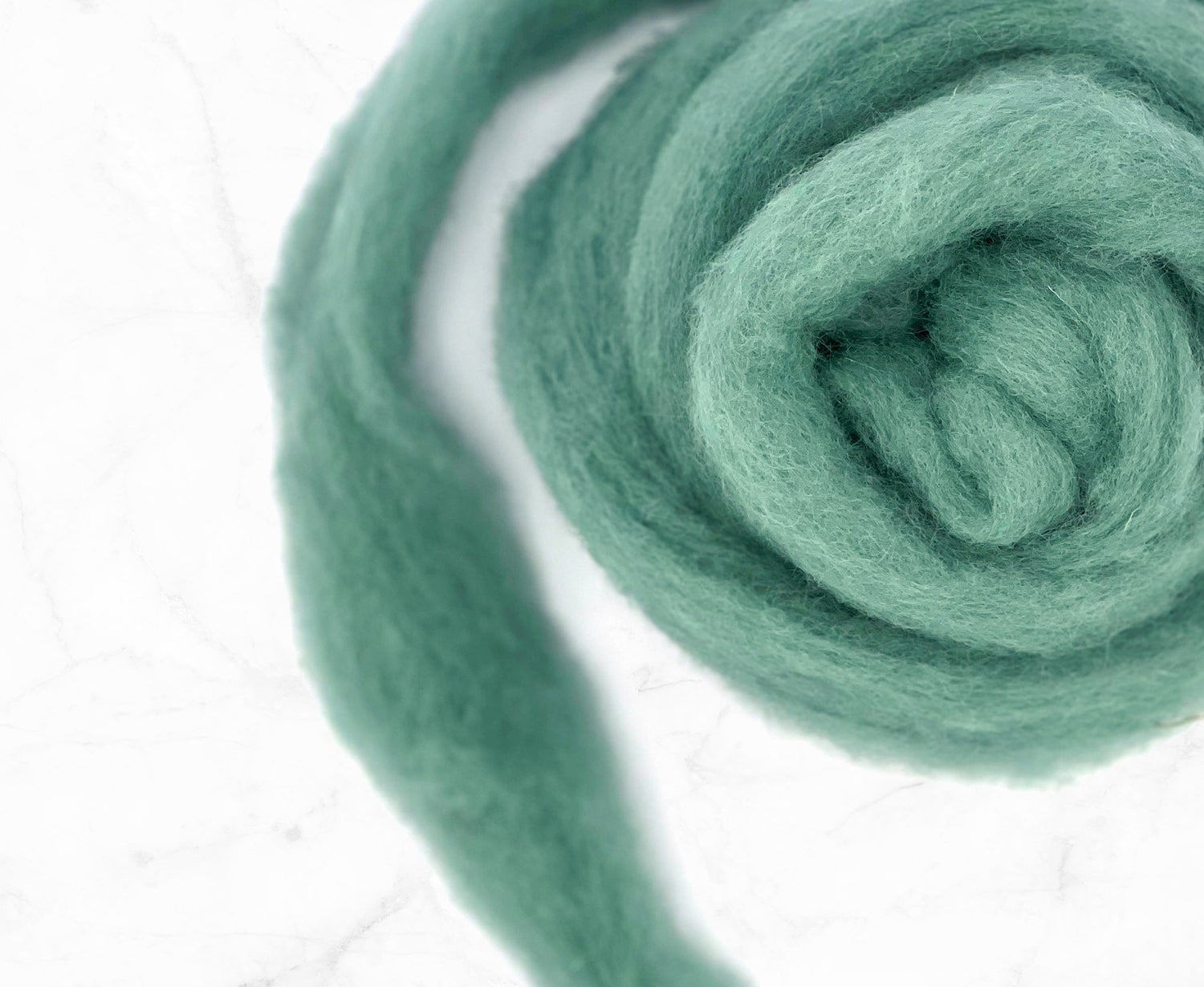

Fibre Focus Friday: Carded Slivers

Our combed tops have always been very popular, but what about our carded slivers?

...And what is carding?

Well, we're glad you asked! Once we've dyed our fleece (or before colour blending, if we're doing one of our blended shades), the clean fleece will be all tangled and could still have bits of grass and all sorts in from when it was on the sheep. Carding encourages the larger pieces to drop out along with some of the coarse fibres. Sometimes small bits of grass seed stay if they are particularly well stuck, but most of the time our machines are pretty good at getting them out!

Why use carded slivers?

Carding makes a web of fibre which can be quite bulky, this makes carded products very good for needle felting and woollen spinning. Carded fibres needle felt more quickly than tops as the fibres are already laying over each other when the needle passes though - it makes the felting easier and quicker. Woollen spun yarns are made using carded fibre; because the fibres are in a web, they trap air between them more readily than combed tops. This means that they spin to a lovely bulky yarn which adds a bit more insulation when knitted or crocheted thanks to the air gap.

You can find all of our carded slivers here.